Explore premium prefab steel storage sheds, warehouses, and construction workshops from Dongguan Hongfa Steel Structure Mats Co., Ltd. Our skilled team provides Auto-CAD/Tekla design services to fulfill all your steel building requirements.

Company Profile:

We have 6 production lines which can fabricate about 5000 ton steel structure materials in a month. Hongfa has a strong technical background with 15 professional engineers who are able to design and do shop drawing with PKPM, Tekla, Auto-cad.

Application:

Discover our versatile steel structure frames, perfect for a variety of building applications. Whether you require a reliable building system for industrial, residential, commercial, airport, train station, or public steel buildings, our frames are the ideal solution. Designed for exceptional durability and strength, our steel structure frames meet the highest standards of quality and safety. Trust Dongguan Hongfa Steel Structure Mats .Co., Ltd. for all your steel structure needs.

Steel Structure Advantages:

1- Short Time and High Efficiency: All steel parts are pre-fabricated at the factory workshop, allowing for quick on-site construction. This reduces project timelines, enabling faster utilization and benefits.

2- Safe, Reliable, and Unbreakable: High-quality steel materials provide strength and protection in harsh environments like typhoon and earthquake zones.

3- Wide Range of Application:Ready-made structural sections can be customized into various shapes and clad with different materials, suitable for industrial, commercial, civil, and public building facilities.

4- Environmentally Friendly and Recyclable:Steel materials are recyclable and do not harm the natural environment.

Main Materials Information:

Explore premium steel construction workshop design services offered by Dongguan Hongfa Steel Structure Mats. Co., Ltd. Our team specializes in Auto-CAD and Tekla design to provide innovative solutions for steel buildings.

| Specifications |

| 1)Size(m): | Width * Length * Height; |

| 2)Type: | Single slope, double slope, Multi-slope;

Single span, double-span, Multi-span;

Single floor, double-floor, Multi-floor; |

| 3) Base: | steel foundation bolts |

| 4) Steel frame: | Material Q345(S355JR)(Gr50)or Q235(S235JR) steel;

Straight cross-section or Variable cross-section;

steel welded H section painted or galvanized. |

| 5) Bracing: | X-type or V-type or other type bracing made from angle, round bar, etc ; |

| 6) Wall & Roof Purlin: | C section channel or Z section channel ,Size from C80~C300; Z100~Z300; |

| 7) Roof & wall cladding | Single color corrugated steel sheet 0.326~0.7mm thickness;

Sandwich panel with EPS, ROCK WOOL,GLASS WOOL, PU etc insulation, thickness around 50mm 75mm 100mm 120mm 150mm 200mm;

recommend coating PVDF SMP HDP PE |

| 8)Window: | UPVC/PVC or Aluminum Alloy window frame with glass. |

| 9)Door: | Exterior door:Sliding or Roller shutter door.

Internal door:50mm thickness EPS sandwich panel with an aluminum alloy door frame |

| 10) Gutter material: | Color steel sheet or galvanized steel or stainless steel; |

| 11)Rainspout: | PVC pipe |

| 12)Connection | high strength bolts ,intensive bolt,self-drilling screws. |

| 13)Accessories: | Skylight panel, Ventilation, Fasteners etc |

| 14)Surface process: | Shot blasting Sa2.5;Two layers of Anti-rust Painting or galvanized |

| 15) Packing: | Main steel frame without packing load in 40' GP, roof and wall panel load in 40' HQ |

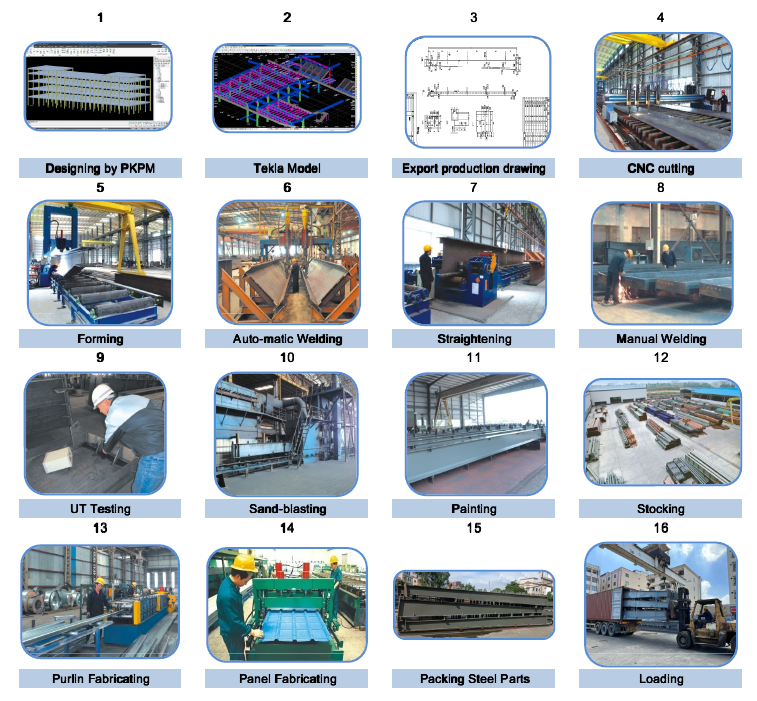

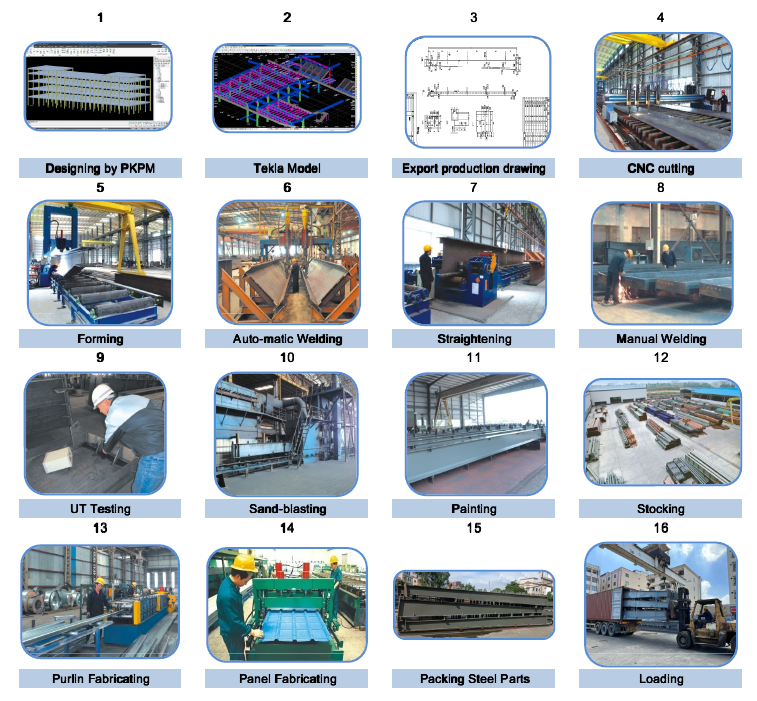

The Whole Processing:

Get top-quality Auto-CAD/Tekla design services for steel workshops. Our expertise includes structural steel analysis, prefab construction, and 50-year warranty. Choose H-Section Steel for lasting durability.

Each Steel Parts and Accessory:

Dongguan Hongfa Steel Structure Mats .Co., Ltd. specializes in providing Steel Construction Workshop Auto-CAD/Tekla Design services for structural steel projects. Our comprehensive solutions cover the entire process from design to construction, ensuring high-quality results.

Factory Show:

Explore our Steel Construction Workshop Design services by Dongguan Hongfa Steel Structure Mats Co., Ltd. Our team of experts utilizes Auto-CAD and Tekla Design to meet all your steel building requirements.